Baltic States – CIS, Construction, Energy, EU – Baltic States, Gas, Transport

International Internet Magazine. Baltic States news & analytics

Thursday, 19.06.2025, 17:03

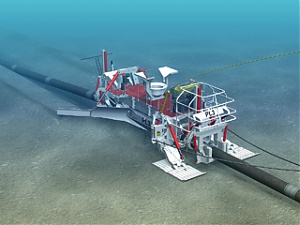

The world’s biggest submarine pipeline plough to entrench Nord Stream pipeline

Print version

Print versionPloughing of the first pipeline is scheduled to be performed at several locations along the pipeline route between early February and mid-March, 2011, informed BC Nord Stream’s press service.

Environmental Monitoring

|

|---|

Model simulations have shown that ploughing will have no significant impact on flora and fauna as sediments will settle quickly. As part of its environmental monitoring programme, Nord Stream will monitor the water quality before, during and after trenching to confirm that the results of the model simulation are correct and that Nord Stream is fulfilling permit requirements.

Subsea ploughs work much in the same way as their land-based farming equivalent, except in this case, the pipeline is passed through a pair of roller boxes in the body of the plough whilst the seabed is excavated by the advancing plough. The PL3 plough will raise the pipeline into its roller boxes using hydraulic grabs, and the plough will then be towed by the Far Samson and create a trench of pre-determined length, depth and width into which the pipeline is laid as the plough advances. Natural sediment movements from waves and currents will gradually backfill the ploughed trench.

Equipment

The PL3 plough used for the Nord Stream project was developed and built in the UK between 2007 and 2009 by IHC Engineering Business for Saipem UK Ltd. It weighs approximately 200 tonnes in air and is 22 metres long. It can excavate a trench up to a maximum depth of 2.5 metres. It is towed by the Far Samson, a purpose-built vessel that was declared Norway’s “Ship of the year 2009”. During the bollard pull test, the Far Samson established a world record when it achieved 423 metric tonnes continuous bollard pull. The Far Samson has a hybrid propulsion system and is very fuel efficient; its generator engines are equipped with catalytic converters which result in 95% NOx reduction.

Construction of the Nord Stream Pipeline started in April 2010, after completion of environmental studies and planning and an Environmental Impact Assessment (EIA) along the entire pipeline route. Three pipelay barges have been commissioned to work on the project: Saipem’s Castoro Sei is carrying out the majority of the construction in the Baltic Sea. The Castoro Dieci has completed its operations in German waters, where it constructed both pipelines in the German landfall section; Allseas’ Solitaire handles construction in the Gulf of Finland as a subcontractor of Saipem. The first pipeline is scheduled to be operational in 2011, the second one in 2012.

«The Baltic Course» Is Sold and Stays in Business!

«The Baltic Course» Is Sold and Stays in Business!